Streamlining the Development Process

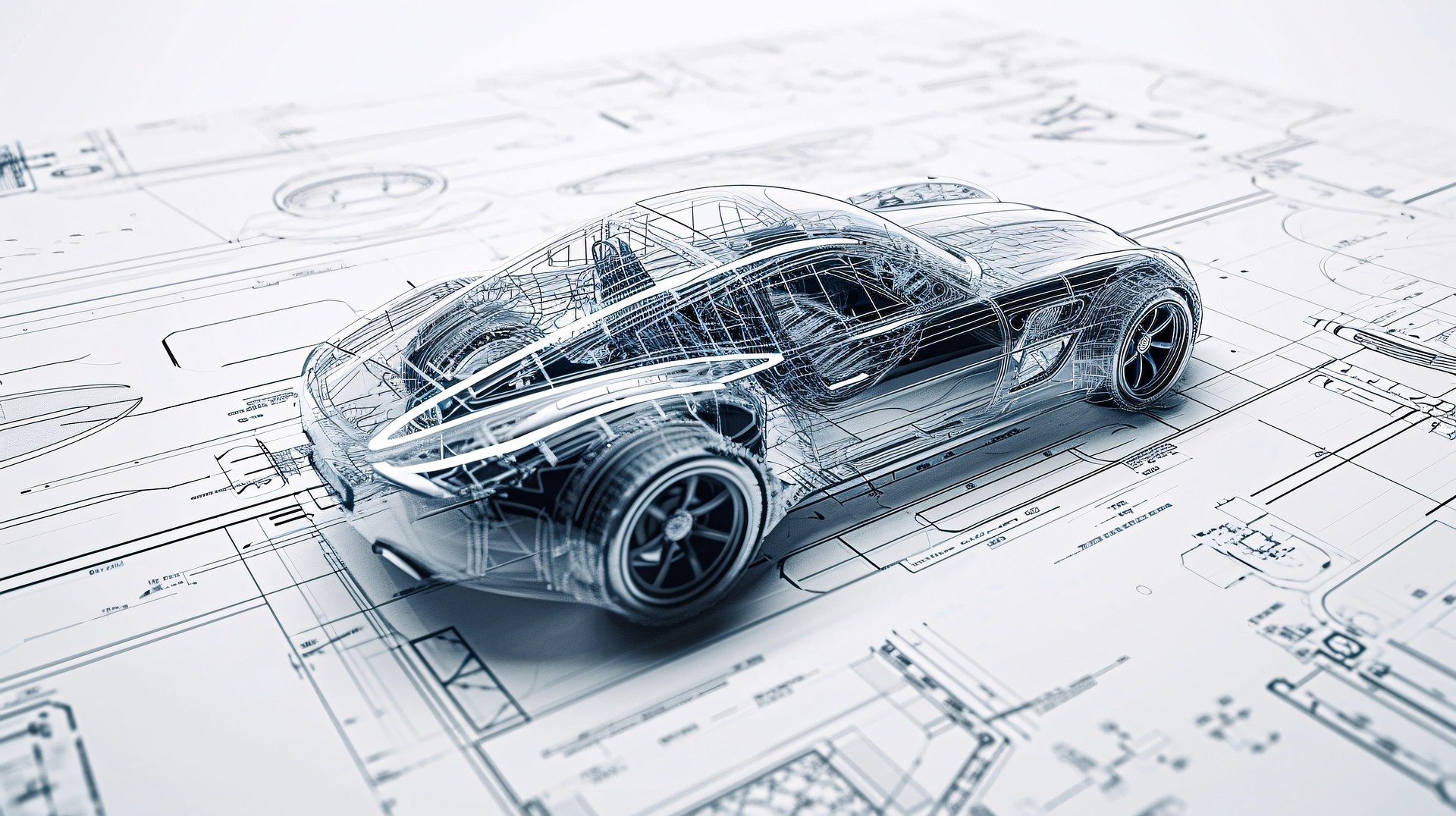

With rapid prototyping, innovation teams can in essence validate their product concepts without investing extensive resources in a project. It also promotes and enhances collaboration with multi-disciplinary teams, fostering creativity and boosting communication. Technologies such as 3D printing and computer aided design (CAD) can now create prototypes within hours, significantly speeding up the development process. Customization, personalization and user experience projects can also be implemented faster.

In Savio’s “Why Rapid Product Prototyping is Essential for Innovation and Speed to Market,” the rapid prototyping service examines the benefits of this process. According to Savio, advantages to the new product development and innovation process include:

- Rapid iteration and design refinement. Traditional development methods require extensive time and resources to create physical prototypes, often resulting in delays and cost overruns. Rapid prototyping speeds up this process by eliminating the need for manual fabrication and enabling quicker design changes.

- Faster decision-making. By providing tangible prototypes for evaluation, companies can gather feedback from stakeholders, end-users, or potential customers, and make informed decisions based on concrete evidence. This iterative feedback loop helps avoid costly mistakes and ensures the final product meets the needs and expectations of its intended audience.

- A culture of innovation. By making it easier to explore ideas and experiment with different designs, materials, and functionalities, companies can push the boundaries of what’s possible and discover new possibilities. Rapid prototyping encourages creative thinking, risk-taking, and a focus on continuous improvement.

- Reduce time-to-market for new products. With the ability to quickly create and test prototypes, companies can identify and address potential issues early in the development process, leading to faster product launches and a competitive edge in the market.

- Collaboration among cross-functional teams. By providing a physical representation of ideas and concepts, prototypes serve as a common ground for discussions and decision-making, bridging the gap between different departments and ensuring everyone is aligned towards the same goal.

The Power of Prototyping

FEI 2025 will hold a session, “Engaging Deliberate Rapid Prototyping.” Explore this dynamic approach to innovation, emphasizing the power of collaborative, cross-functional teams. We’ll delve into strategies for aligning diverse perspectives from product innovation, development, insights, and marketing to accelerate the prototyping process. Discussion will center on early-stage alignment; strategic stakeholder engagement; “last question first” methodology; “quick win” focus; data-informed decision-making; and expanding influence.

The session will be presented by Tammy Butterworth, Product Innovation Director at Welch’s; Paige Palmieri, Innovation Sr. Scientist at Welch’s; Heidi Hitchen, Senior Manager, Consumer Insights at Welch’s; Sarah Princehorn, Transformational Innovation Manager at Welch’s; Christian Lavoie, Senior Manager, Consumer & Market Insights at Welch’s; and Brian Leslie, Interim Head of Transformational Innovation at Welch’s.

Embracing Rapid Prototyping

Savio recommends starting the rapid prototyping process early in the development phase. Balance such traits as quality and speed. That’s not to say there aren’t some challenges to implementing these programs into your innovation plan. According to Savio, common challenges could include:

- Cost: Rapid prototyping can be expensive, especially for complex designs or when using certain materials. Careful cost-benefit analysis and budgeting are necessary to ensure the investment is justified.

- Time constraints: Rapid prototyping requires time and resources. Companies need to allocate dedicated resources, manage expectations, and plan for the additional time required for prototyping and testing.

- Technical expertise: Successfully implementing rapid prototyping often requires specialized knowledge and skills. Companies may need to invest in training or seek external expertise to maximize the benefits.

- Integration with existing processes: Introducing rapid prototyping into existing development processes can be challenging. Companies need to ensure the smooth integration of prototyping activities without disrupting the overall workflow.

Still, despite these constraints, rapid prototyping is only expected to grow in importance for the innovation and new product development process in such fields as automotive, healthcare, architecture and fashion. Already, technology such as 3D printing is making rapid prototyping systems more accessible. In the future, Savio points to growing trends such as new materials, integration with artificial intelligence, on-demand manufacturing and bio-fabrication which will further enhance these systems.

As Savio notes, “As technology continues to advance and the demand for innovation intensifies, rapid prototyping will remain a cornerstone of product development. The ability to quickly and cost-effectively create physical prototypes that can be tested, refined, and validated is invaluable in today’s competitive landscape… Companies that embrace rapid prototyping as a key component of their product development process will be better positioned to seize opportunities, drive innovation, and succeed in the face of ever-evolving customer demands.”

Video courtesy of Formlabs